Larger Titanium Parts Made to a Higher Standard

Avalign Thortex’s patented metal injection molding (MIM) process not only delivers the cost savings and weight reduction of other MIM operations, but also allows us to create larger parts, including titanium components that meet strict American Society for Testing and Materials (ASTM) standards.

Bigger Parts

Avalign Thortex’s patented metal injection molding process produces larger titanium parts than other MIM manufacturers.

Lighter Weight

Our net shape process makes lighter weight titanium parts without compromising strength.

ASTM Approved

Avalign Thortex produces larger titanium parts with low oxygen to meet advanced medical standards.

Expanded Metal Injection Molding Applications

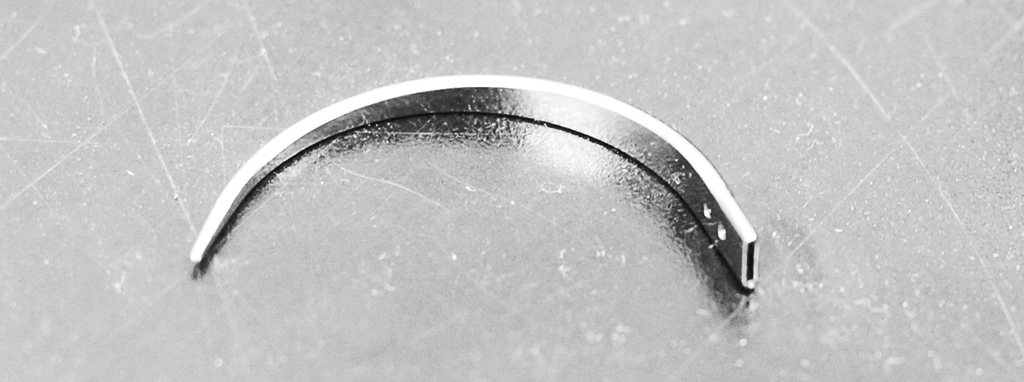

Avalign Thortex’s metal injection molding process enables us to offer a wider variety of joint implant components made with ASTM-approved titanium. In addition to typical MIM pieces, Avalign Thortex can produce larger parts including:

• Knee Femorals

• Hip Stems

• Shoulder Stems

• Elbow Ulnar Stems

• Elbow Radial Stems

How Avalign Thortex Metal Injection Molding Works

Instead of expensive traditional machining, which is subtractive, Avalign Thortex uses a patented additive manufacturing process to shape raw material into the desired part design. Then, we add heat and pressure to condense the metal into a dense, yet lightweight, product.

Typical MIM processes are limited in part size, especially with titanium alloys. While our process can use stainless steel or titanium, Avalign Thortex’s patented metal injection molded titanium process incorporates proprietary procedures that meet stringent ASTM standards for large parts measured in pounds and kilograms rather than ounces and milligrams.

Avalign Thortex Metal Injection Molding Gives You More Options

Take advantage of a lower cost production process for a wider range of product options with Avalign Thortex’s unique metal injection molding process. With Avalign Thortex’s MIM procedures, you get larger titanium parts that meet the highest ASTM standards. Learn more about the facility that manufactures our metal injection molding products.

Choose Avalign Thortex metal injection molding to reduce costs and improve production flexibility. Contact your Avalign Thortex sales representative to learn more.